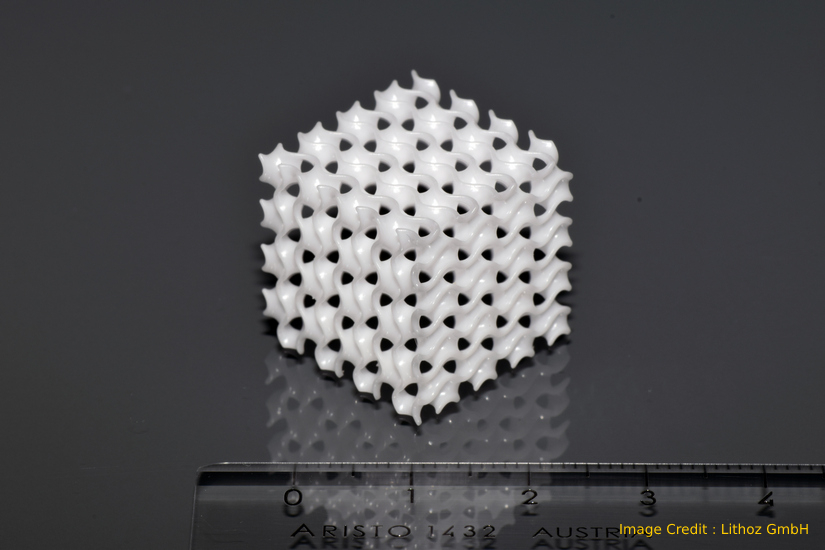

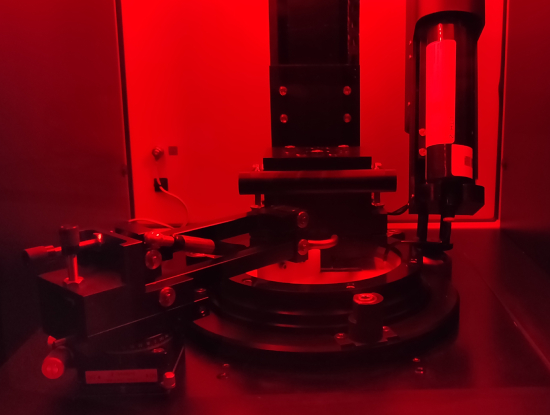

- High resolution printing process – micron precision/ good dimensional fidelity

- High quality surface finish – minimal post-processing – material dependant

- High density and bulk material properties equivalent or superior to conventional ceramics

- High production rate/ fast machine turnaround

- Economical raw materials usage/ recycles unused raw materials

- Multi-material capability/ material changeovers in a few minutes

- Energy efficient process

Why Ceramic Additive Manufacturing

Benefits of Ceramic 3D Printing

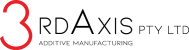

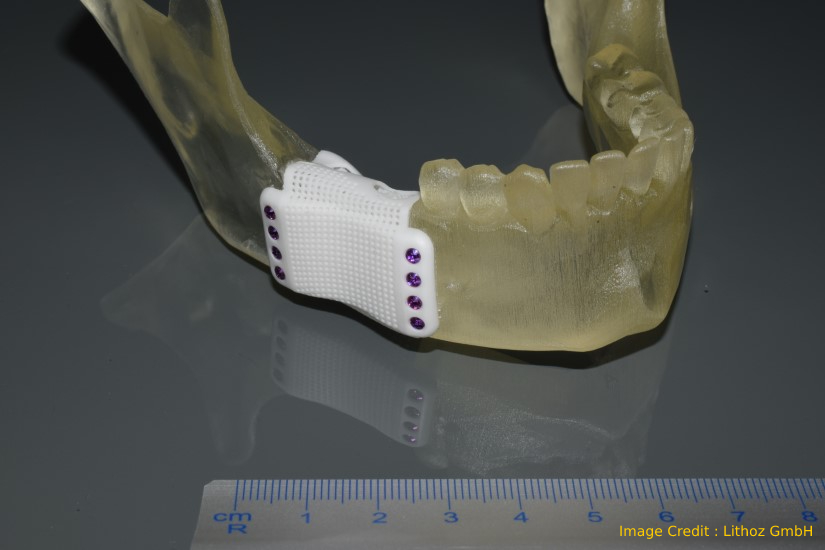

- Design Flexibility – geometry practically only limited by the designer’s imagination

- Part Consolidation – making one part instead of using many pieces joined together

- Strong Lightweight Parts – use of CAD/ 3D Modelling leads to efficient structures

- Part Complexity – realises geometries not achievable by other manufacturing methods

- Part Geometry – realises precision internal holes, channels and passages not usually possible in ceramic parts

- Part Properties – sintered AM parts exhibit good flexural, compressive and impact strength

- No supplementary tooling – reduced cycle times and fast turn-around

- Minimum Order Quantity of one – no need for large batch sizes/ orders

- Short Production Lead Times – parts can be delivered in days not weeks or months

- Rapid Iteration during New Product Development Phase

Case Studies

How We WorkImplementation Process

Easy process to implement ceramic product

additive manufacturing with 3rdAxis